|

ANPING COUNTY WANHAI METAL PRODUCTS TRADING CO., LTD.

|

DOUBLE TWIST STEEL ROAD MESH

| Price: | 1.0~2.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

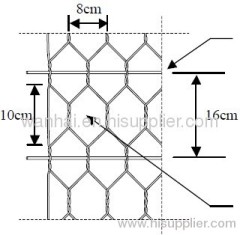

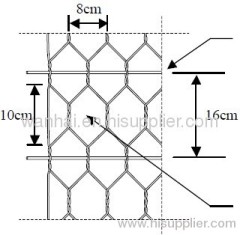

Road Mesh is manufactured from double twisted steel wire mesh with transverse reinforcing rods evenly spaced throughout at approximately 16 cm centre.

Road Mesh was initially introduced to intercept the reflected cracks generated by

jointed concrete pavements. Wider use of the product and further research have found

the steel mesh being used more widely and for a greater number of solutions.

The steel mesh is best suited to be used for the following applications:

- Fatigue cracking and overlays: if a new pavement or if a new overlay is installed

over a fatigued/cracked pavement, cracks will propagate to the surface after a very short

traffic period. Road Mesh is introduced to extend the life of the overlay by absorbing

the horizontal tensile stresses resulting from the existing cracks and by traffic loads.

- Road widening: when roads need to be widened, differential settlement cracks

occur at the junction between the old and new pavement structures. Road Mesh is

introduced to bridge the junction to absorb the crack stresses caused by the differential

settlement: the effective interlock with the asphalt aggregate matrix ensures the

optimum contribution of the reinforcement; a minimum of 1 m either side of the joint is

required.

- Surface rutting: under repeated heavy vehicle traffic, the asphalt surfacing is

exposed to repeated shear forces which result in shear slip circles and ultimately leads

to shoving. Road Mesh is installed at the base of the overlay, for a layer thickness more

than 60 mm, thus intersecting the shear slip circle and ultimately reduces the surface

rutting.

The double twist steel mesh was initially introduced to intercept the reflected cracks

generated by jointed concrete pavements. Wider use of the product and further research

have found the steel mesh being used more widely and for a greater number of

applications, as the steel mesh is able to absorb the stresses induced by a reflected crack

generated by a jointed crack; to intercept the shear plane to provide rut resistance and to

reduce the peak tensile stress and strain under load. Configuration of the current steel

wire mesh reinforcement consists of a double-twist, hexagonal mesh transversally

reinforced at regular intervals with steel wires inserted in the double twist.

Several research groups have been investigating the effectiveness of the reinforcement

both by laboratory tests and numerical modelling, with a variety of finite element

models adopted to characterize the reinforced.

jointed concrete pavements. Wider use of the product and further research have found

the steel mesh being used more widely and for a greater number of solutions.

The steel mesh is best suited to be used for the following applications:

- Fatigue cracking and overlays: if a new pavement or if a new overlay is installed

over a fatigued/cracked pavement, cracks will propagate to the surface after a very short

traffic period. Road Mesh is introduced to extend the life of the overlay by absorbing

the horizontal tensile stresses resulting from the existing cracks and by traffic loads.

- Road widening: when roads need to be widened, differential settlement cracks

occur at the junction between the old and new pavement structures. Road Mesh is

introduced to bridge the junction to absorb the crack stresses caused by the differential

settlement: the effective interlock with the asphalt aggregate matrix ensures the

optimum contribution of the reinforcement; a minimum of 1 m either side of the joint is

required.

- Surface rutting: under repeated heavy vehicle traffic, the asphalt surfacing is

exposed to repeated shear forces which result in shear slip circles and ultimately leads

to shoving. Road Mesh is installed at the base of the overlay, for a layer thickness more

than 60 mm, thus intersecting the shear slip circle and ultimately reduces the surface

rutting.

The double twist steel mesh was initially introduced to intercept the reflected cracks

generated by jointed concrete pavements. Wider use of the product and further research

have found the steel mesh being used more widely and for a greater number of

applications, as the steel mesh is able to absorb the stresses induced by a reflected crack

generated by a jointed crack; to intercept the shear plane to provide rut resistance and to

reduce the peak tensile stress and strain under load. Configuration of the current steel

wire mesh reinforcement consists of a double-twist, hexagonal mesh transversally

reinforced at regular intervals with steel wires inserted in the double twist.

Several research groups have been investigating the effectiveness of the reinforcement

both by laboratory tests and numerical modelling, with a variety of finite element

models adopted to characterize the reinforced.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Double Twist Wire

Double Twist Machine

Road Mesh

Road Mesh Fence

Road Wire Mesh Fence

Road Barrier Mesh

More>>