|

ANPING COUNTY WANHAI METAL PRODUCTS TRADING CO., LTD.

|

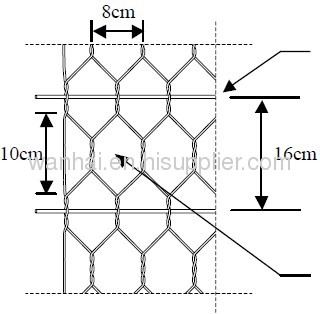

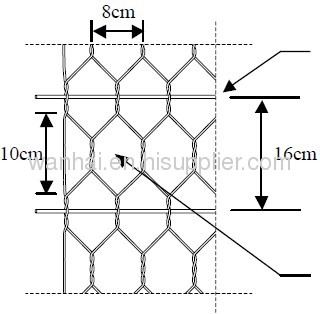

Reinforcing double twist steel wire mesh

| Price: | 1.0~2.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

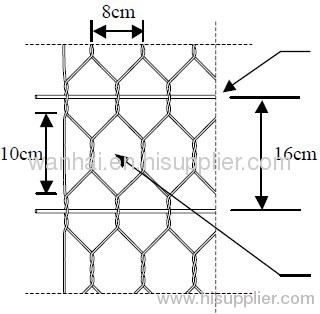

Road Mesh is manufactured from double twisted steel wire mesh with transverse reinforcing rods evenly spaced throughout at approximately 16 cm centre.

double twist wire mesh with Transverse Reinforcing Rod, because it used in road reinforcement products also called road mesh.

Road Mesh is manufactured from double twisted steel wire mesh with transverse reinforcing rods evenly spaced throughout at approximately 16 cm centre.

The double twist steel mesh was initially introduced to intercept the reflected cracks

generated by jointed concrete pavements. Wider use of the product and further research

have found the steel mesh being used more widely and for a greater number of

applications, as the steel mesh is able to absorb the stresses induced by a reflected crack

generated by a jointed crack; to intercept the shear plane to provide rut resistance and to

reduce the peak tensile stress and strain under load. Configuration of the current steel

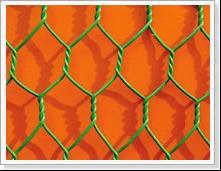

wire mesh reinforcement consists of a double-twist, hexagonal mesh transversally

reinforced at regular intervals with steel wires inserted in the double twist.

Several research groups have been investigating the effectiveness of the reinforcement

both by laboratory tests and numerical modelling, with a variety of finite element

models adopted to characterize the reinforced.

1. The hexagonal mesh size is 80 by 100 mm (nominal) as defined

in EN 10223-3, the wire is protected against corrosion by a zinc coating complying with

EN 10244-2 Class A. The mesh thickness varies between the 2.4 mm wire diameter up

to 9.2 mm where the transverse rod passes through the double twist. The varying height

of the product strands, and distance between them, ensures that the asphalt can

encapsulate the wire, without developing a weak shear zone at the product interface.

Table 1: Mechanical characteristics of Road Mesh

Wire diameter(mm):2.4;

ransverse rod (mm)4.4;

Tensile strength MD/XD(kN/m);39/50

Road Mesh is manufactured from double twisted steel wire mesh with transverse reinforcing rods evenly spaced throughout at approximately 16 cm centre.

The double twist steel mesh was initially introduced to intercept the reflected cracks

generated by jointed concrete pavements. Wider use of the product and further research

have found the steel mesh being used more widely and for a greater number of

applications, as the steel mesh is able to absorb the stresses induced by a reflected crack

generated by a jointed crack; to intercept the shear plane to provide rut resistance and to

reduce the peak tensile stress and strain under load. Configuration of the current steel

wire mesh reinforcement consists of a double-twist, hexagonal mesh transversally

reinforced at regular intervals with steel wires inserted in the double twist.

Several research groups have been investigating the effectiveness of the reinforcement

both by laboratory tests and numerical modelling, with a variety of finite element

models adopted to characterize the reinforced.

1. The hexagonal mesh size is 80 by 100 mm (nominal) as defined

in EN 10223-3, the wire is protected against corrosion by a zinc coating complying with

EN 10244-2 Class A. The mesh thickness varies between the 2.4 mm wire diameter up

to 9.2 mm where the transverse rod passes through the double twist. The varying height

of the product strands, and distance between them, ensures that the asphalt can

encapsulate the wire, without developing a weak shear zone at the product interface.

Table 1: Mechanical characteristics of Road Mesh

Wire diameter(mm):2.4;

ransverse rod (mm)4.4;

Tensile strength MD/XD(kN/m);39/50

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Steel Reinforcing Mesh

Double Twist Wire

Reinforcing Wire

Wire Reinforcing

Double Crimped Wire Mesh

Double Wire Mesh Fence

More>>