|

ANPING COUNTY WANHAI METAL PRODUCTS TRADING CO., LTD.

|

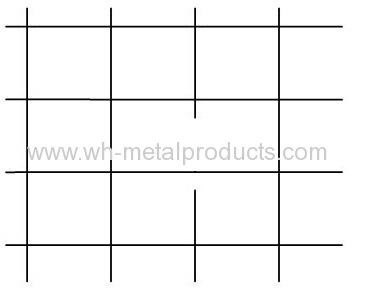

extruder filtration black wire cloth screen and filter discs

| Price: | 2.0~5.0 USD |

| Payment Terms: | T/T,L/C,D/P,WU |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

WANHAI wire cloth screen for extruder filtration,mainly used in plastic and rubber processing machinery to ensure a clean and viable extrusion.

wire cloth screen for extruder filtration is used in plastic and rubber processing machinery to ensure a clean and viable extrusion.

Extruder screen wire cloth is essential in preventing contamination in the melted mass during the extrusion process. It is effect to keeps away mixing of foreign particles in finally equipped extrusion product and provide a clean and clear extrusion to use. Mainly used for filtration of plastics and rubber processing industry, chemical and pharmaceutical industry.

wire cloth extruder screen benefits:

1. To filter out contaminants and improve mixing and product purity, reduce your maintenance and repair costs.

2. With smooth screening surface with no sharp edges, burrs or acute angles.

3. Available in different size, variants and specifications.

4. Highly durable with robust structure.

5. Anti-abrasive & anti-corrosive in nature.

6. High quality and filtration capacity.

7. Precise fitting filter elements.

8. Optimum cost-performance ratio.

9.Constant quality control during production.

Extruder screens are an imperative part of the melt filtration process, it is available in various materials:

carton steel wire, plain steel wire, stainless steel wire, no nickel no magnetic stainless steel wire,high tensile steel wire.

wire cloth for extruder filtration screen weaves all with a wide spectrum of micron ratings to suit different filter use.

Standard Extruder Screen Size | |||

Mesh | Wire Dia. mm | Aperture Size mm | Open Area |

10×10 | 0.711 | 1.829 mm | 51.8 |

14×14 | 0.457 | 1.357 mm | 55.9 |

16×16 | 0.457 | 1.131 mm | 50.7 |

20×20 | 0.559 | 0.711 mm | 31.4 |

20×20 | 0.457 | 0.813 mm | 41.0 |

24×24 | 0.376 | 0.682 mm | 41.4 |

30×30 | 0.376 | 0.531 mm | 34.2 |

30×30 | 0.310 | 0.536 mm | 40.0 |

40×40 | 0.274 | 0.361 mm | 32.3 |

50×50 | 0.193 | 0.335 mm | 43.6 |

60×60 | 0.193 | 0.230 mm | 29.8 |

80×80 | 0.122 | 0.196 mm | 37.9 |

100×100 | 0.102 | 0.152 mm | 36.0 |

120×120 | 0.091 | 0.120 mm | 31.8 |

150×150 | 0.071 | 0.088 mm | 29.6 |

200×200 | 0.050 | 0.077 mm | 36.76 |

250×250 | 0.040 | 0.062 mm | 36.76 |

300×300 | 0.040 | 0.045 mm | 27.83 |

325×325 | 0.035 | 0.043 mm | 30.49 |

400×400 | 0.028 | 0.036 mm | 31.25 |

500×500 | 0.025 | 0.026 mm | 25.79 |

Extruder screens weave ways :plain weave,dutch weave,twill weave,herringbone weave,reverse dutch weave.

| twill weave/herringbone weave | ||

| mesh | wire diamter | widthxlength |

| SPG40 | 0.35mm | 1X30M |

| SPG30 | 0.45mm | 1X30M |

| SPG24 | 0.40mm | 1X30M |

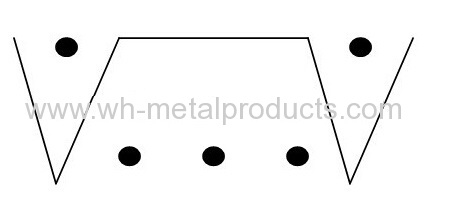

dutch weave Wire cloth

Mesh/Inch | Wire Diameter | Absolute Filtration Fineness µm | Nominal Filtration Fineness µm |

8X85 | .014X.0126 | 318 - 340 | 250 - 255 |

12X64 | .024X.0165 | 270 - 285 | 200 - 205 |

14X88 | .020X.013 | 225 - 245 | 150 - 155 |

20X150 | .0098X.007 | 155 - 165 | 100 - 105 |

24X100 | .015X.010 | 115 - 125 | 80 - 85 |

30X150 | .009X.007 | 95 - 100 | 65 - 70 |

40X200 | .007X.0055 | 65 - 70 | 55 - 60 |

50X250 | .0055X.0045 | 55 - 60 | 40 - 45 |

80X400 | .0049X.0028 | 43 - 48 | 35 - 40 |

Dutch weave wire mesh quality problem

when we test the wire mesh (dutch weave),we need pay close attention to several common quality problems,

hole of mesh;

common mesh problem,wire broken

top cramp,when weave the ducth wire cloth, the warp wire loose,easily formed wire top cramp;

4. plain steel wire cloth usually have this quality problem-wire connection,while stainless steel wire cloth not

have this problem seldom,because stainless steel wire have more stronger strength.

5. double weft is a small defect in black wire cloth weaving.

6.longitude sheer-density pin

7.latitude sheer-density pin

8. greasy dirt-plain steel wire cloth quality problem

9. wire cloth amplitude problem usually apper in stainless steel dutch wire cloth, plain steel twill weave wire cloth, black wire cloth, low carbon steel wire cloth.

10.jumper wire, this quality problem usually appear in dutch weave wire cloth, plain steel dutch weave wire cloth,black wire cloth

11.wire cloth quality problem example

loose construction of net, soft net

12.rusty spot is the fatal quality problem in plain steel wire cloth.

plain steel wire cloth is woven by low carbon steel wire, after dipped in oil, use the wire weave wire cloth,then make into filter disc, used in all kinds of filter industry, because the low cost, plain steel wire cloth is very popular in market, however, because it is not galvanized, must pay attention to moistureproof, rust prevention, especially in summer, once rusty spot appear, pls do the rust cleaning, spray oil, incase the rust increase.