|

ANPING COUNTY WANHAI METAL PRODUCTS TRADING CO., LTD.

|

assembled welded mesh container barrier

| Price: | 20.0~50.0 USD |

| Payment Terms: | T/T,L/C,D/P,WU |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

wholesale welded mesh defence security barrier,used for defensive firing position hesco bastion, wire mesh defence bastion.fast installing,save labour

1. welded mesh defence security barrieris is a collapsible wire mesh container with a heavy duty non-woven polypropylene liner. Open in up and use a front end loader to fill it with sand (dirt or gravel) and you have a protective barrier to protect personnel and equipment from enemy fire (or bombs).

2.The labor saving angle is very popular with the troops. Before the HESCO barriers, troops filled sandbags, which was slow. One soldier could fill about 20 sandbags an hour. Troops using Hesco barriers and a front end loader can do ten times the work of troops using sandbags.

(A) The Hesco barriers come in a variety of sizes designed for military work.

(B)And also,the sections of HESCO are being linked together and filled with sand to create a flood barrier from the rising waters of the Red River. U.S

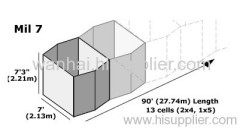

3.Dimensions

Material: galvanized welded mesh, spring with other fittings, can be filled with sand, earth, cement, stone. Can be used in separate cell or some cells joint together.

Wire diameter: 3mm-5mm

Mesh opening size: 50mm-75mm

Panel size: The hesco Barriers come in a variety of sizes. Most of the barriers can also be stacked, and they are shipped collapsed in compact sets. Example dimensions of typical configurations are 4'6" x 3'6" x 32' (1.4m x 1.1m x 9.8m) to 7' x 5' x 100' (2.1m x 1.5m x 30m)., it also can be customized according to customer's requirement

Geotextile: in heavy duty non-woven polypropylene

Finish: hot dipped galvanized, electro galvanized

Packing: wrapped with shrink film or packed in pallet.

Wire diameter: 3mm-5mm

Mesh opening size: 50mm-75mm

Panel size: The hesco Barriers come in a variety of sizes. Most of the barriers can also be stacked, and they are shipped collapsed in compact sets. Example dimensions of typical configurations are 4'6" x 3'6" x 32' (1.4m x 1.1m x 9.8m) to 7' x 5' x 100' (2.1m x 1.5m x 30m)., it also can be customized according to customer's requirement

Geotextile: in heavy duty non-woven polypropylene

Finish: hot dipped galvanized, electro galvanized

Packing: wrapped with shrink film or packed in pallet.

4.Application

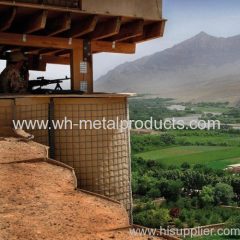

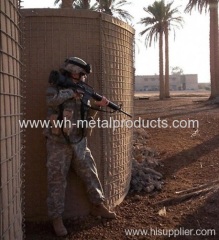

Perimeter security and defence walls

Equipment revetments

explosive and contraband search areas

Ammunition compounds

Personnel and material bunkers

Observation points

Defensive firing positions

Highway checkpoints

Border crossing checkpoints

Protection existing structures

High way traffic management

Flood control

Water courses

Emergency flood deployment

Erosion control

Retaining walls

5.Features

Easy to handle and install

High tensile and anti-impact capability

Long life, regular use

Can be filled with sand, earth, cement, stone.

Perimeter security and defence walls

Equipment revetments

explosive and contraband search areas

Ammunition compounds

Personnel and material bunkers

Observation points

Defensive firing positions

Highway checkpoints

Border crossing checkpoints

Protection existing structures

High way traffic management

Flood control

Water courses

Emergency flood deployment

Erosion control

Retaining walls

5.Features

Easy to handle and install

High tensile and anti-impact capability

Long life, regular use

Can be filled with sand, earth, cement, stone.

6. Assembly

Assembling the Hesco Bastion entails unfolding it and (if available) using a front end loader to fill it with sand, dirt or gravel. The placement of the barrier is generally very similar to the placement of a sandbag barrier or earth berm except that room must generally be allowed for the equipment used to fill the barrier. The main advantage of Hesco Barriers, strongly contributing to their popularity with troops and flood fighters, is the quick and easy setup. Previously, people had to fill sandbags, a slow undertaking, with one worker filling about 20 sandbags per hour. Workers using Hesco Barriers and a front end loader can do ten times the work of those using sandbags.

A new system of Hesco Bastion developed specially for military use is deployed from a container, which is dragged along the line of ground where the barrier is to be formed, unfolding up to several hundred meters of barrier in minutes, ready for filling with soil by a backhoe.

7.Protection

Filled with sand, 60 centimetres (24 inches) of barrier thickness will stop rifle bullets and shell fragments. It takes 1.5 metres (five feet) of thickness to prevent penetration by a rocket propelled grenade round(although these usually do not hit at the right angle to need that much thickness, but just explode creating a lot of fragments.). Approximately 1.2 metres (four feet) of thickness provides protection against most car bombs.

Assembling the Hesco Bastion entails unfolding it and (if available) using a front end loader to fill it with sand, dirt or gravel. The placement of the barrier is generally very similar to the placement of a sandbag barrier or earth berm except that room must generally be allowed for the equipment used to fill the barrier. The main advantage of Hesco Barriers, strongly contributing to their popularity with troops and flood fighters, is the quick and easy setup. Previously, people had to fill sandbags, a slow undertaking, with one worker filling about 20 sandbags per hour. Workers using Hesco Barriers and a front end loader can do ten times the work of those using sandbags.

A new system of Hesco Bastion developed specially for military use is deployed from a container, which is dragged along the line of ground where the barrier is to be formed, unfolding up to several hundred meters of barrier in minutes, ready for filling with soil by a backhoe.

7.Protection

Filled with sand, 60 centimetres (24 inches) of barrier thickness will stop rifle bullets and shell fragments. It takes 1.5 metres (five feet) of thickness to prevent penetration by a rocket propelled grenade round(although these usually do not hit at the right angle to need that much thickness, but just explode creating a lot of fragments.). Approximately 1.2 metres (four feet) of thickness provides protection against most car bombs.

The Hesco barriers have prevented hundreds of casualties among US troops and done wonders for morale.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Safety Barrier Mesh

Traffic Barrier Mesh

Road Barrier Mesh

Welded Mesh

Wire Mesh Container

Mesh Box Container

More>>